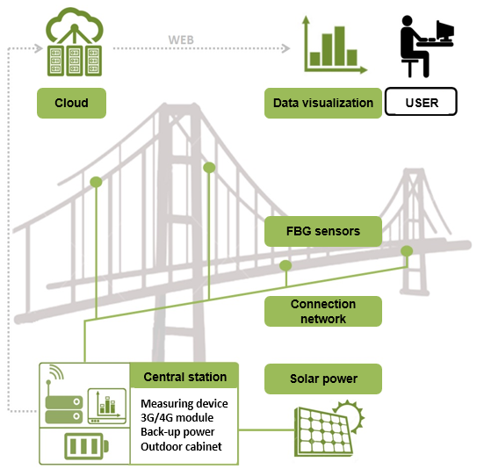

Monitoring systems utilizing fiber optic sensors are critical components in various industries, providing real-time, accurate, and efficient data collection for a wide array of applications. Elaborating on the intricacies of these systems involves understanding their fundamental components, operation principles, and diverse applications.

Components of Fiber Optic Monitoring Systems:

Fiber Optic Cables: These cables transmit light signals and are the backbone of the monitoring system. They are made of glass or plastic fibers that carry light over long distances without significant loss of signal strength.

Optical Transmitters: These devices generate light signals that travel through the fiber optic cables. They can be LEDs (Light Emitting Diodes) or laser diodes, emitting light at specific wavelengths.

Optical Receivers: Positioned at the end of the fiber optic cables, these devices detect the light signals and convert them back into electrical signals for processing.

Signal Processing Units: These units interpret the electrical signals received from the optical receivers. They can perform various tasks such as amplification, filtering, and digitization of the signals.

Data Analysis Software: This software analyzes the processed data, identifies patterns, trends, and anomalies, and presents actionable insights to the end-users.

Operation Principles:

- Optical Interference: Fiber optic sensors rely on the principle of optical interference, where changes in the environment alter the properties of the light traveling through the fiber. These changes can include variations in temperature, pressure, strain, or the presence of specific chemicals.

- Modulation Techniques: Various modulation techniques, such as intensity modulation, phase modulation, or frequency modulation, are employed to encode the measured parameter information onto the light signal transmitted through the fiber.

- Interrogation Methods: Different interrogation methods, including time-domain reflectometry (TDR), frequency-domain reflectometry (FDR), and interferometric techniques, are used to extract the sensor data from the returned light signal.

- Multiplexing: To monitor multiple parameters simultaneously or over long distances, multiplexing techniques like wavelength division multiplexing (WDM) or time division multiplexing (TDM) are utilized.

Applications:

- Structural Health Monitoring (SHM): Fiber optic sensors are employed in monitoring the structural integrity of buildings, bridges, dams, and pipelines by measuring parameters like strain, temperature, and vibration.

- Oil and Gas Industry: In the oil and gas sector, fiber optic sensors are used for distributed temperature sensing (DTS) along pipelines, detecting leaks, monitoring wellbore conditions, and measuring fluid properties.

- Aerospace and Defense: Fiber optic sensors play a crucial role in aerospace applications for monitoring aircraft structures, engine performance, and flight control systems. They are also used in defense applications for perimeter security, battlefield surveillance, and missile guidance systems.

- Medical Monitoring: Fiber optic sensors are utilized in medical applications for minimally invasive diagnostics, monitoring vital signs, and tracking drug delivery within the body.

- Environmental Monitoring: These sensors help in environmental monitoring by measuring parameters such as water quality, soil moisture, and air pollution levels.

Advantages:

- High Sensitivity: Fiber optic sensors offer high sensitivity, enabling the detection of minute changes in the monitored parameters.

- Electromagnetic Immunity: They are immune to electromagnetic interference, making them suitable for use in environments with high electromagnetic noise.

- Long-distance Monitoring: Fiber optic cables can transmit signals over long distances without significant signal degradation, allowing for remote monitoring in challenging environments.

- Compact Size and Flexibility: Fiber optic sensors are compact, lightweight, and flexible, making them suitable for installation in tight spaces and harsh operating conditions.

- Multiplexing Capability: The ability to multiplex multiple sensors over a single fiber optic cable reduces installation costs and complexity while increasing the amount of data that can be collected.

Challenges:

- Cost: Fiber optic monitoring systems can be expensive to install and maintain, primarily due to the cost of the components and specialized expertise required for deployment.

- Fragility: Fiber optic cables are delicate and prone to damage from bending, crushing, or environmental factors such as temperature extremes or moisture.

- Complexity: Designing and implementing fiber optic monitoring systems require a deep understanding of optical physics, signal processing, and data analysis techniques, which can be challenging for inexperienced users.

- Calibration and Maintenance: Regular calibration and maintenance are essential to ensure the accuracy and reliability of fiber optic sensors, adding to the operational overhead.

- Data Interpretation: Interpreting the vast amount of data generated by fiber optic sensors and distinguishing between normal variations and potential threats or anomalies can be complex and time-consuming.

In conclusion, fiber optic monitoring systems offer unparalleled capabilities for real-time, high-fidelity data collection across a wide range of applications. However, their deployment requires careful consideration of the specific requirements, challenges, and trade-offs involved to ensure optimal performance and reliability.